COMPRESSORS - OUR PORTFOLIO

A HIGH-TECH PRODUCT THANKS TO CUTTING-EDGE TECHNOLOGY

We get gaseous media moving with virtually no wear, no external air supply and absolutely oil-free.

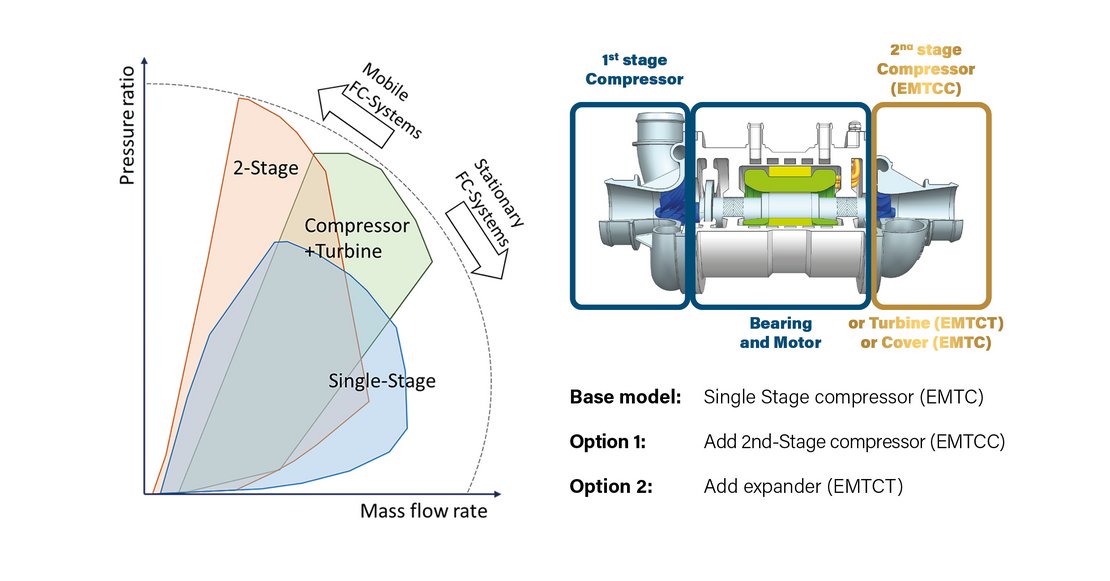

Our compressors ensure innovative and environmentally friendly mobility: thanks to maximum power density and controllable mass flows, they enable efficient operation of fuel cells. This reduces the number of layers required in the stack and optimizes hydrogen consumption. The additional turbine further reduces hydrogen consumption. The aim is to realize the complete fuel cell system in an even more cost-optimized way.

Our turbo compressors, which are designed in Switzerland, offer impressive performance in a compact system design. Space savings as well as low weight give more room for customer requirements. FISCHER compressors include a sophisticated electric drive and quickly bring the optimized compressor wheels to maximum speed. Our products have been designed with a spiral groove bearing system for long lasting operation in stationary or transportation applications. In our test facilities we have demonstrated over 200’000 start stop cycles and wear-free operation of well over 25’000 hours.

Here you will find an overview of our standard air compressors, which are based on a common platform concept and can be adapted to almost all customer requirements.

EMTC

Electric Micro Turbo Compressor

EMTCT

Electric Micro Turbo Compressor with turbine for energy recovery

EMTCC

Electric Micro Turbo Compressor with two compressor stages (parallel or serial)

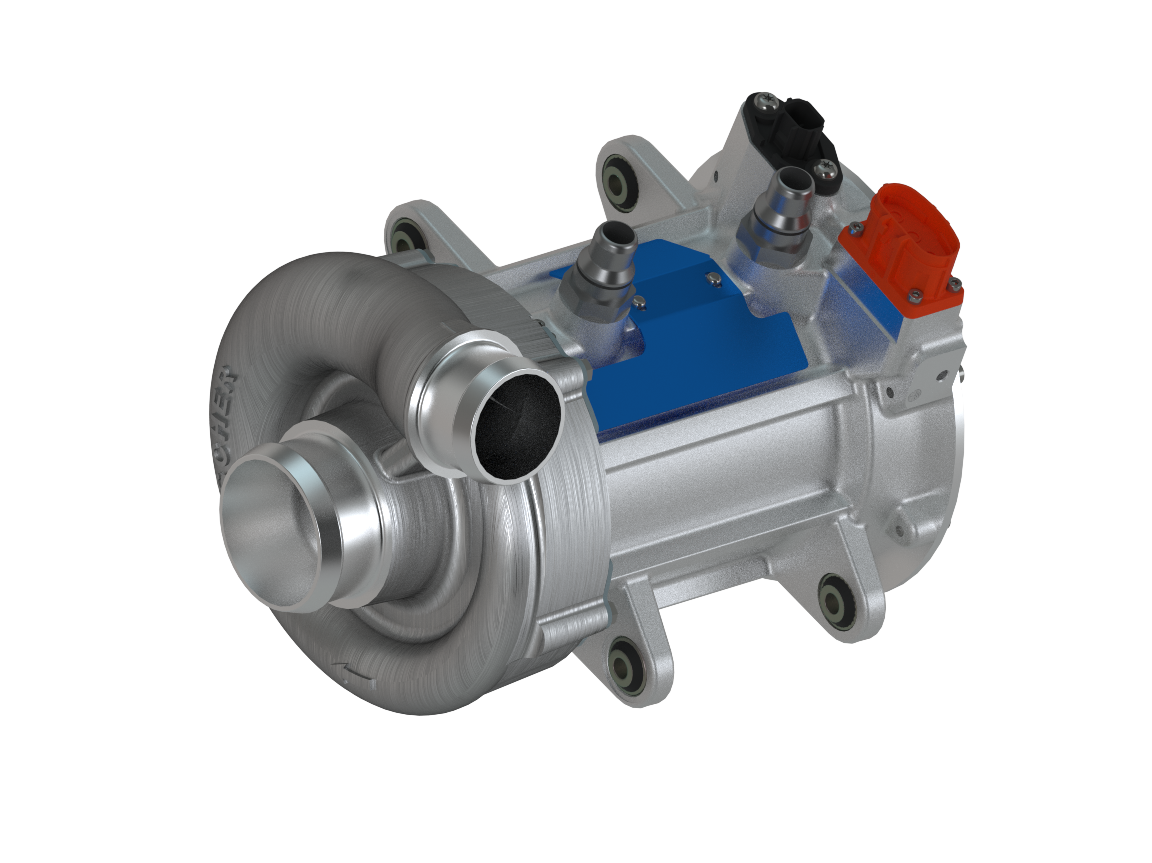

EMTC-150K Air

Standard compressor

5.7kW, 150krpm

The EMTC-150k compressor system is designed for fuel cell systems in the power range up to 70kW. Our compressor systems can be adapted to customer requirements through aerodynamic adjustments.

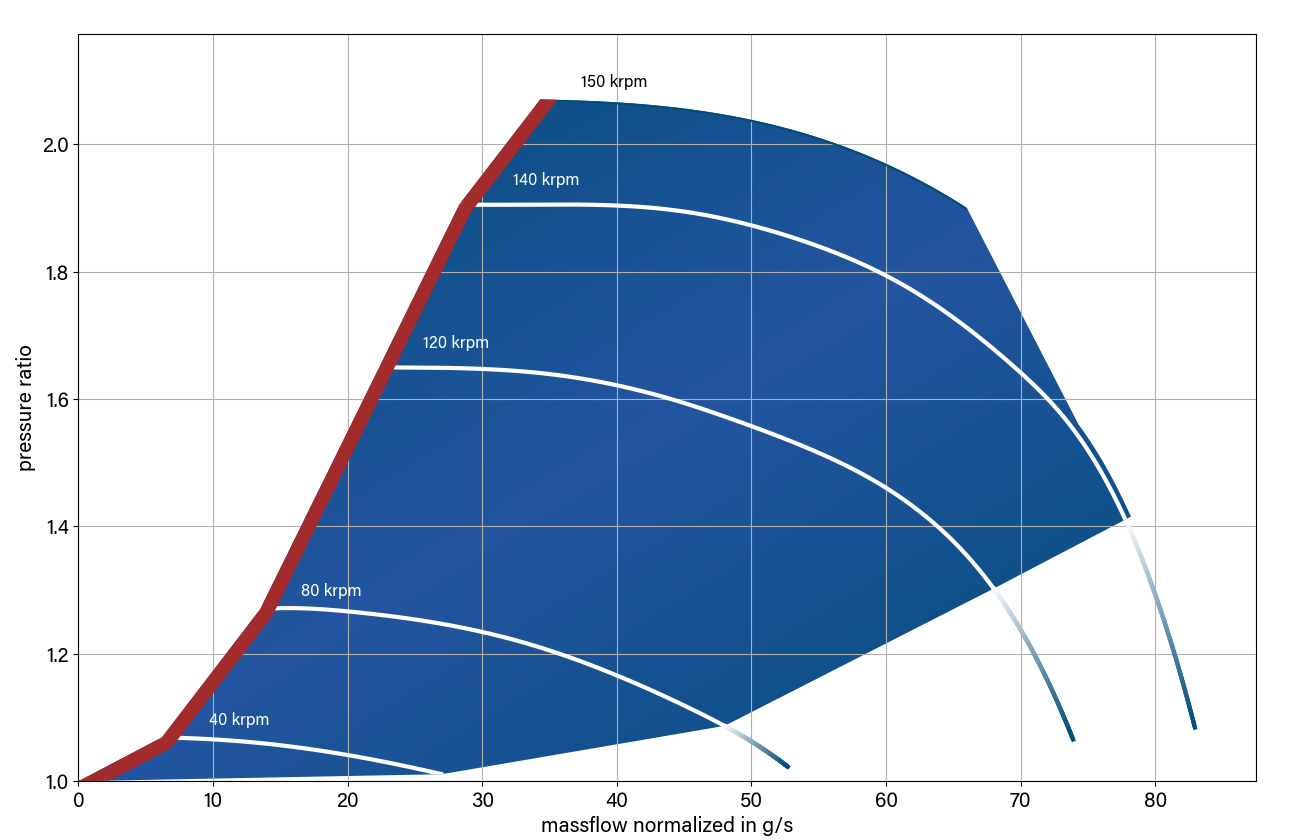

EMTC-120K Air GEN4

Standard compressor

22.5kW, 120krpm

The EMTC-120k compressor system is designed for fuel cell systems in the 80-150kW power range. Our compressor systems can be adapted to customer requirements through aerodynamic adjustments.

EMTCT-120K Air GEN4

Standard compressor with turbine

22.5kW, 120krpm

The EMTCT-120k compressor system is designed for fuel cell systems in the 80-150kW power range. Our compressor systems can be adapted to customer requirements through aerodynamic adjustments.

EMTCC-120K Air GEN4

Two-stage compressor for highest pressure ratio

22.5kW, 110krpm

The EMTCC-120k compressor system is designed for fuel cell systems in various power ranges. Our compressor systems can be adapted to customer requirements through aerodynamic adjustments.

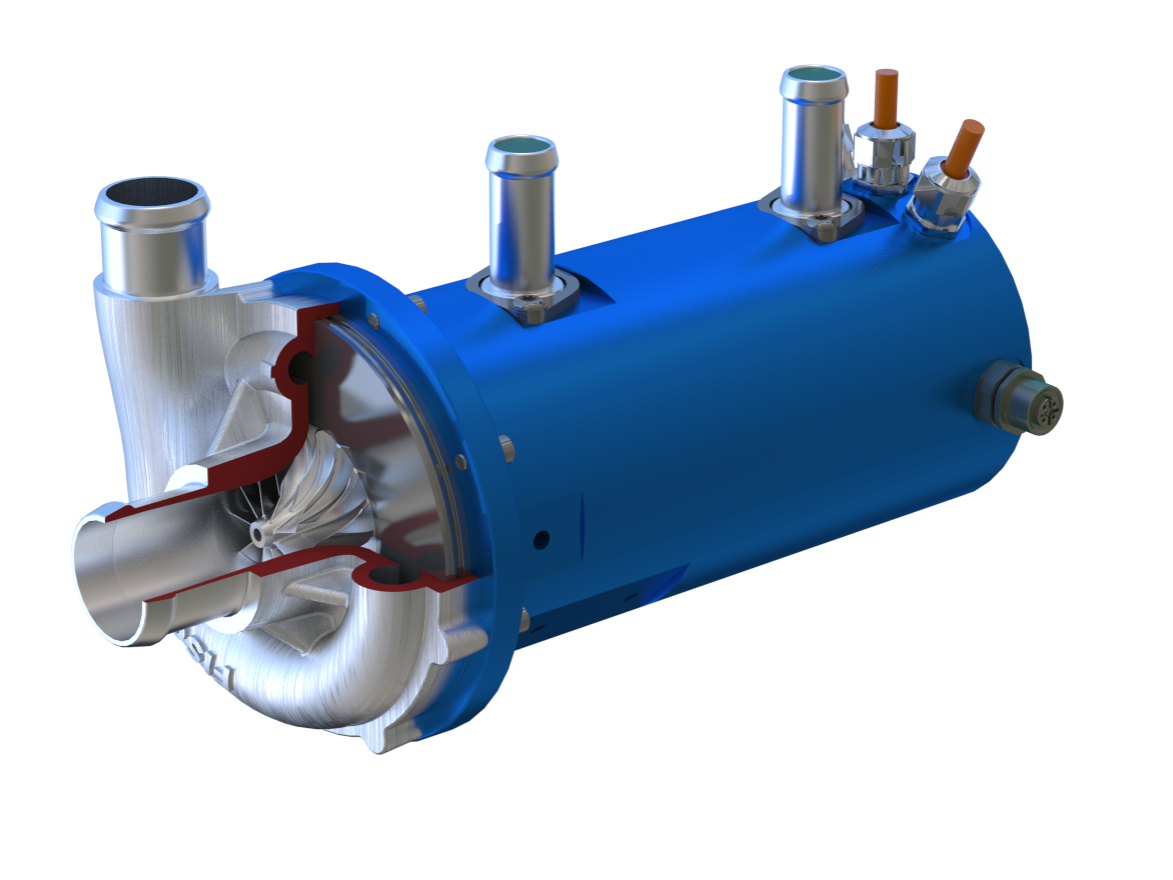

EMTC-90K Air GEN5

Standard compressor

38kW, 92krpm

The EMTC-90k compressor system is designed for fuel cell systems in the 150-300kW power range. Our compressor systems can be adapted to customer requirements through aerodynamic adjustments.

EMTCT-90K Air GEN5

Standard compressor with turbine

38kW, 92krpm

The EMTCT-90k compressor system is designed for fuel cell systems in the 150-300kW power range. Our compressor systems can be adapted to customer requirements through aerodynamic adjustments.

Water separator

In order to further increase the efficiency of the fuel cell system, it is possible to obtain additional energy from the exhaust air flow of the fuel cell. This is usually realised with a turbine on the turbo air compressor. In this way, the efficiency of the turbo compressor can be increased by up to 30%. To ensure that the water from the fuel cell exhausted air does not damage the turbine, proper water management is essential. FISCHER Fuel Cell Compressor has developed a specially adapted and uniquely efficient water separator for fuel cell applications. The size is matched to fuel cell systems from 80-150kW with the EMTCT-120k Air compressor. With the unique and patented principle, the service life of the entire compressor system can be significantly increased.

Here you can find the current factsheet.

SERVICE

WE OFFER YOU THE TAILOR-MADE SOLUTION

We meet individual customer wishes and requirements with tailor-made Swiss high-tech solutions, thus ensuring the realization of coordinated hydrogen fuel cell systems with optimum efficiency and power density.